Emulsifying essence is made by adding appropriate emulsifier and stabilizer to oil-soluble essence and dispersing it in water. Under the action of emulsifier, the water-insoluble oil-soluble essence is dispersed into a stable emulsion made by shear homogenization.

Emulsified flavor is widely used in beverage industry because it has the function of enhancing fragrance and turbidity. In many beverages, it is not only required that the beverage has a delicious taste and pleasant aroma, but also needs to have a certain degree of turbidity, so that the beverage has a natural sense of reality, so it is necessary to use emulsified flavor to emulsify. In addition, it is often used in cosmetics such as hair lotion, hair cream and powder. It is characterized by mild aroma and preservative effect.

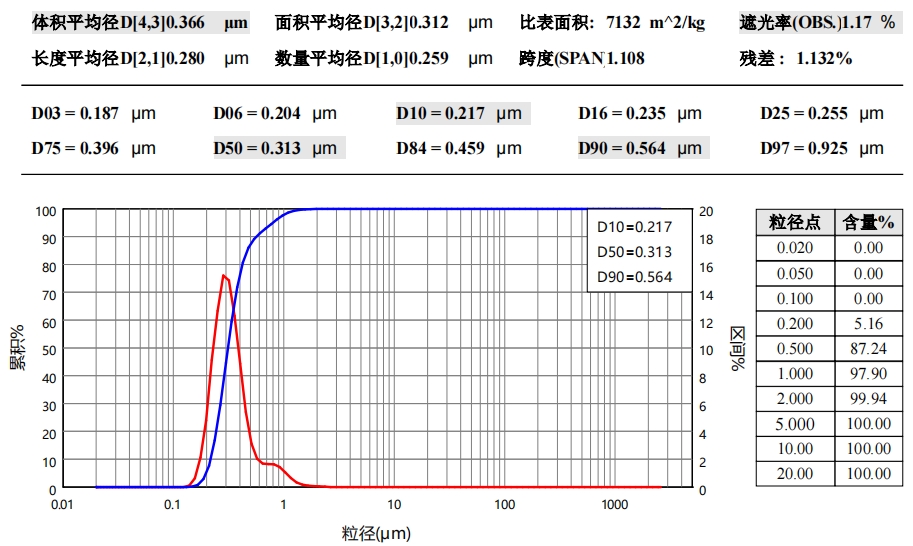

At present, the commonly used preparation technology of emulsion flavor is to cut oil phase to water phase at high speed, and then to prepare by high pressure homogenization emulsification. In emulsions, it is important to control the size of dispersed (oil) phase particles. When the diameter of the dispersed phase particles is greater than 2um, the observed solution is two-phase separation. When the diameter of dispersed phase particles is 1 ~ 2um, the solution is milky white. When the diameter of dispersed phase particles is 1-0.1 um, the solution is blue-white. When the particle diameter of dispersed phase is less than 0.05um, the solution will turn into transparent liquid. According to Stokes' law, the smaller the particle diameter of the dispersed phase, the better, but for emulsified flavors, the problem of natural turbidity should still be considered. The emulsion stability of essence with particles greater than 1.2um will decrease. Emulsion essence with particle less than 0.1um will have no turbidity when used in beverages; The particle size is between 0.5 and 1.2um, which can produce the best emulsion effect. The size of dispersed phase (oil phase) particles in emulsion essence is mainly controlled by high pressure homogenizing equipment.

ATS high pressure homogenization mechanism to prepare emulsified essence

▶ The emulsion essence after homogenization is bluish white after shaking, and the particle size of D90 reaches 564nm.

The above experimental data comes from ATS Complex Preparation Center, more emulsion flavor preparation process questions, welcome to call: 400-998-7088; You can also send samples or come to our company to test in person, ATS is happy to serve you.