1. Carbon nanotubes

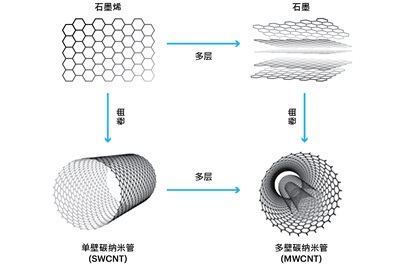

Carbon nanotubes are divided into two categories - single-walled carbon nanotubes (SWCNTs) and multi-walled carbon

nanotubes (MWCNTs). Single-walled carbon nanotubes are seamless hollow cylinders formed by rolling up single-walled

graphene sheets, while multi-walled carbon nanotubes are concentric arrangements of single-walled carbon nanotubes,

that is, multi-layer graphene sheets are seamlessly rolled up into tubes.

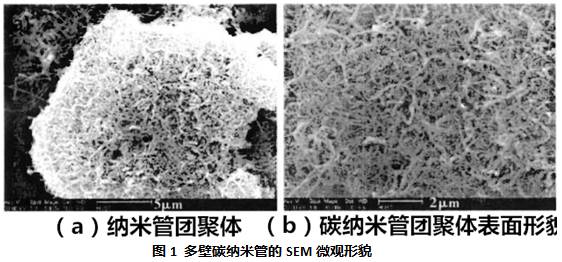

At the beginning of the formation of multi-walled pipes, it is easy to become a trap center between layers and capture various

defects, so the wall of multi-walled pipes is usually covered with small holes like defects. Compared with multi-wall tube, single-wall

tube has smaller diameter distribution range, fewer defects and higher uniformity.

2. Application field

Electronic field

Carbon nanotubes can be used not only to make molds for nanowires, but also to make wires themselves. Using the electronic

properties of carbon nanotubes, they can be used to make transistor initiation circuits or micro-sensor elements. It can also be

used as a positive and negative electrode of lithium-ion batteries, so that the battery life is increased, and the charge and discharge

performance is good. In addition, carbon nanotubes are considered to be a promising material for the manufacture of a new generation

of flat screen displays.

Composite material field

Because of their excellent electrical and mechanical properties, carbon nanotubes are considered as the ideal addition phase for composite

materials. Carbon nanotubes (CNTS), as the strengthening phase and conductive phase, have great application potential in the field of nanocomposites.

New energy field

Hydrogen storage - carbon nanotube hydrogen storage is one of the applications with great potential. At room temperature and atmospheric pressure,

about two-thirds of the hydrogen can be released from the carbon nanotubes, and can be used repeatedly.

Super nano carbon fiber battery - light weight, only 1/10 of the weight of lead-acid battery, the volume is only 1/16 of the general battery, widely used in

electric vehicles, submarines, electric locomotives and other electric power machinery that needs large energy storage and light weight.

Medical and bioengineering fields

An important property of carbon nanotubes is that they can cross cell membranes and a variety of barriers in the biological body, and enter cells and a

variety of organs in the biological body. Drugs based on carbon nanotubes provide great hope for cancer.

Environmental protection field

Using the characteristics of nano-scale dust particles to develop new moisturizing materials, greatly improve the water retention capacity of soil, and

improve the success rate and speed of greening. It is hoped that the development and application of this new technology can effectively solve the crisis

of soil desertification caused by soil weathering and water loss in desertified areas.

Third, application difficulties

Carbon nanotubes (CNTS) are nanoscale fiber materials, which have the strong agglomeration effect of nano-powders and the entanglement bonding phenomenon of fiber materials. All kinds of effects are superimposed, the adsorption force of carbon nanotube aggregates is greater, the binding is closer, and the dispersion is more difficult. Therefore, in order to obtain uniformly dispersed carbon nanotubes, three conditions must be met at the same time: destroying the entanglement bond state of long fibers, overcoming the strong adsorption force of aggregates, and stabilizing the dispersion state of carbon nanotubes.

4. ATS dispersion experiment

1. Experimental equipment

ATS nano dispersion homogenizer

Water cooler

viscometer

2. Experimental process

ATS nano dispersion homogeneity machine controlled low temperature and high pressure treatment 3 times

3. Experimental purpose

The dispersion viscosity is less than 3000

4. Experimental results

A. Experimental phenomena

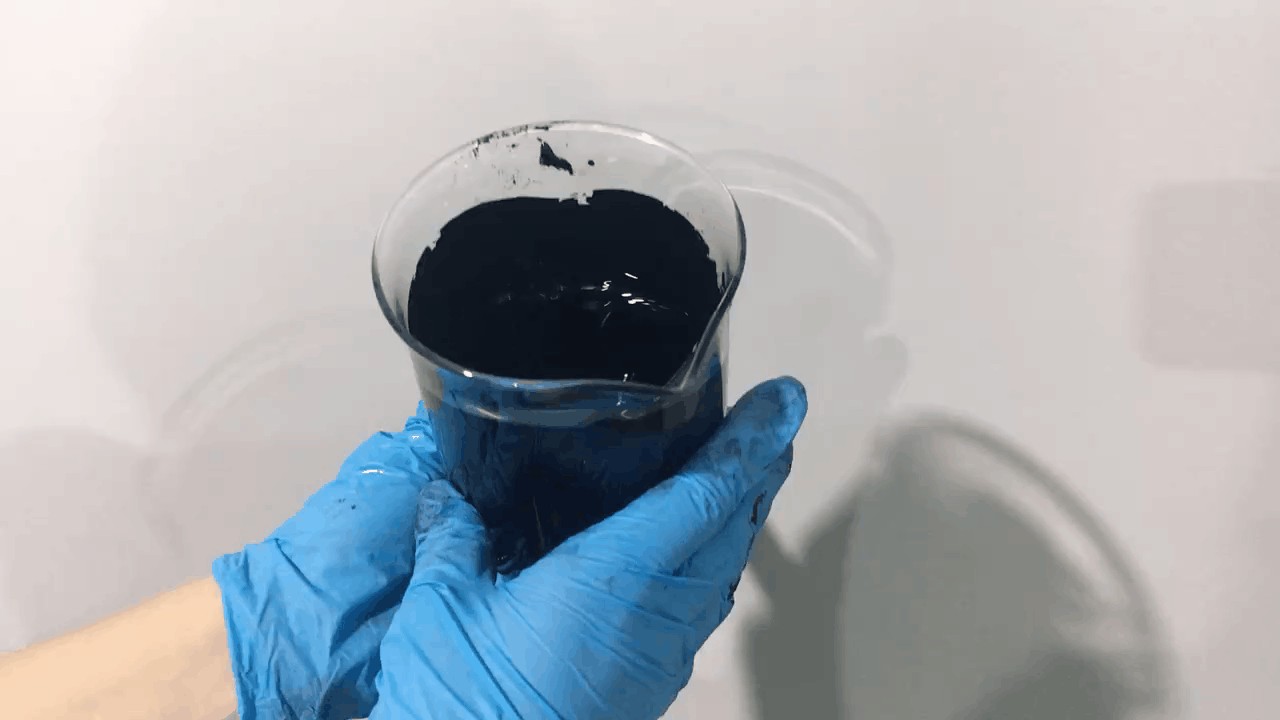

Before dispersion, the sample is viscous and has poor fluidity. After dispersion, the fluidity of the sample is enhanced,

and water ripple occurs when shaking.

Before

After

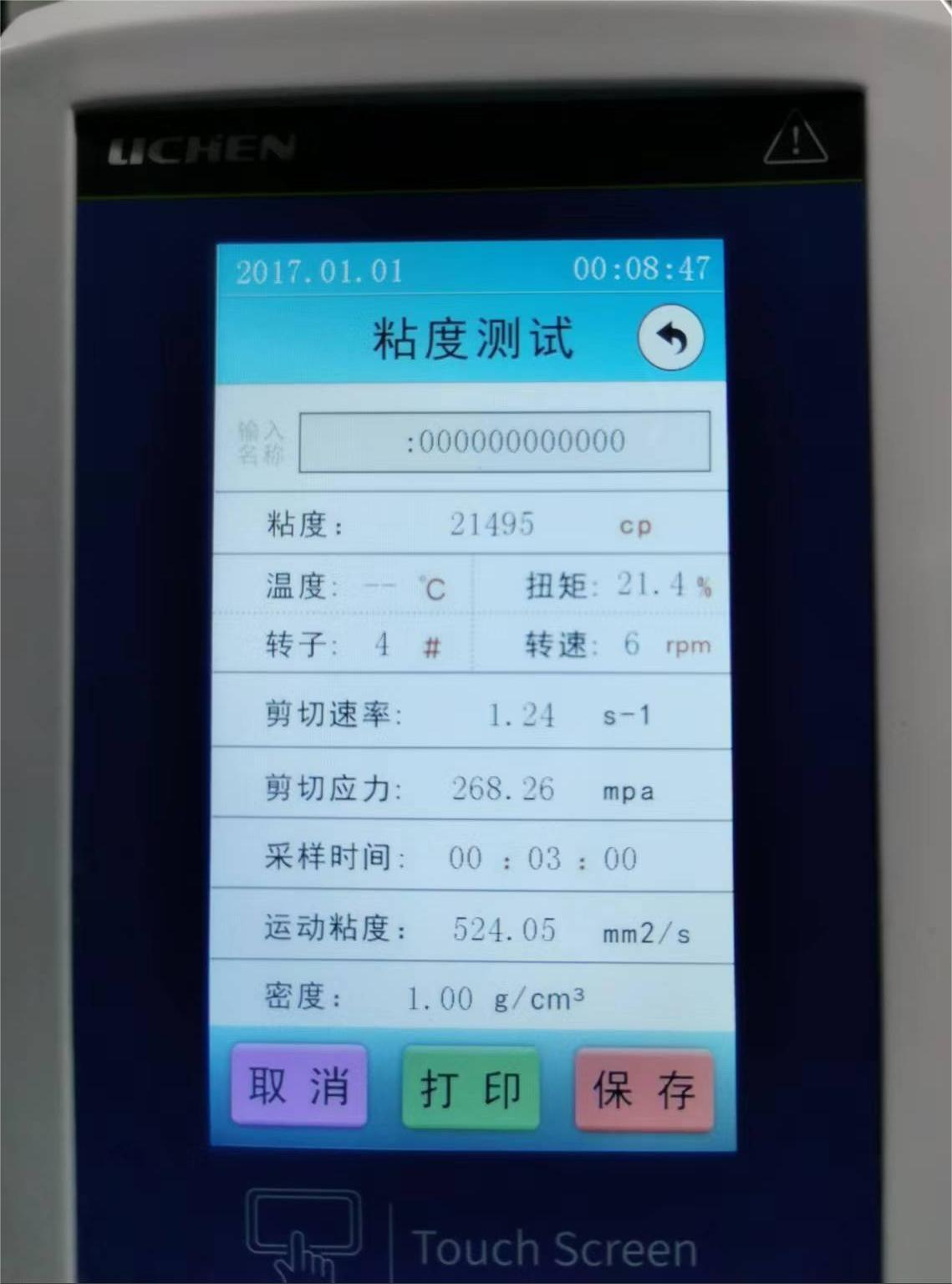

B. Viscosity detection

After ATS nano dispersion and homogenization, sample viscosity decreased from 21495CP to 2563CP to meet customer demand.