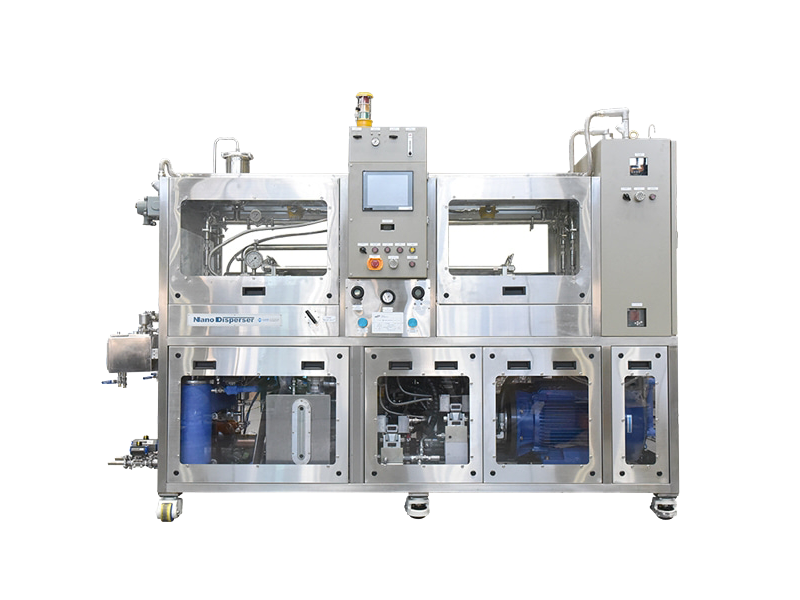

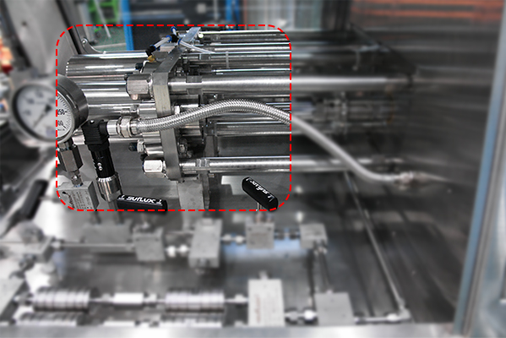

The high-pressure fluid quickly passes through the narrow gaps in the dispersion unit. At this time, the pressure in the fluid drops sharply to form a supersonic flow rate. The particles in the fluid collide, cavitate and leak. The shear force acts on splitting nanometer-sized molecules. Exists in a completely homogeneous state. Its unique diamond micro-channel beaming technology can obtain extremely small and uniform nano-scale particle size distribution results, and the hydraulic booster power mode can provide stable working pressure up to 200Mpa.